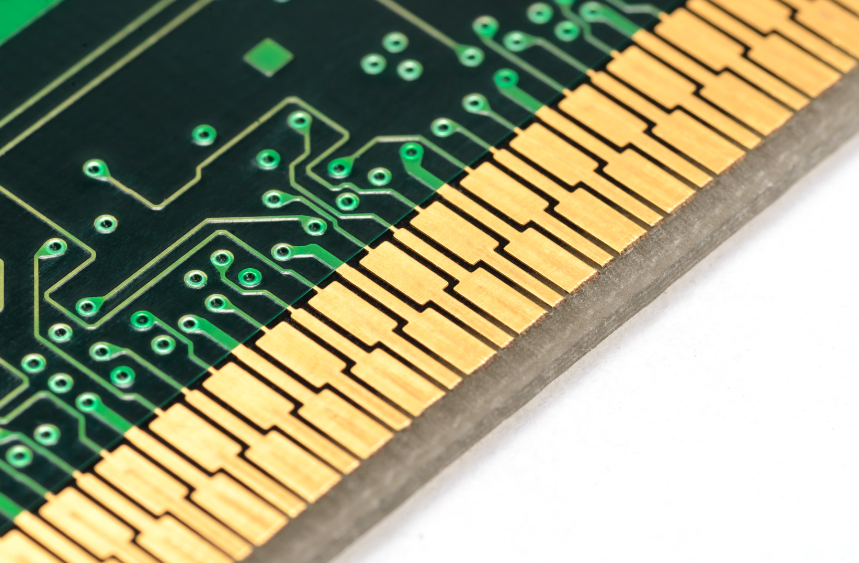

Preventing Oxidation of Gold-Plated PCBs

More from the Category

Gold-plated PCBs are the backbone of high-reliability electronic systems, from aerospace instruments to cutting-edge medical devices. Their unmatched conductivity and resistance to tarnish make them a preferred choice for many applications. However, even these premium components are not immune to the effects of oxidation. Over time, exposure to moisture, environmental pollutants, and improper handling can lead to the gradual degradation of the gold surface. This process, often unnoticed until failure occurs, compromises electrical performance and system reliability.

Preventing PCB oxidation is more than just a manufacturing challenge — it's a necessity for ensuring the longevity and functionality of electronic assemblies. This article dives into the causes of oxidation, explores its effects on gold-plated PCB boards, and offers actionable strategies for maintaining their integrity. Whether you're troubleshooting field failures or refining manufacturing practices, understanding how to prevent PCBs from oxidation is essential for every professional in the electronics industry.

Understanding Oxidation in Gold-Plated PCBs

Oxidation is a natural chemical process that occurs when a material reacts with oxygen in its environment. While gold is highly resistant to oxidation due to its inert nature, the materials it is plated over — typically copper or nickel — are far more vulnerable. This underlying vulnerability is a key concern for gold-plated PCB boards, especially when protective measures are lacking or improperly implemented.

The Science of Oxidation

In gold-plated PCBs, oxidation usually occurs not on the gold itself but on the layers beneath. For example, copper oxidation occurs if the gold layer is thin or uneven and oxygen penetrates through microcracks to react with the copper underneath. This leads to delamination or discoloration, as seen in poorly manufactured boards. In ENIG boards, the nickel barrier beneath the gold can oxidize if exposed to air, which reduces solderability and electrical performance over time.

Performance Implications

Even small amounts of oxidation can degrade PCB functionality in the following ways:

Increased Contact Resistance: Oxidation interferes with the metal's ability to form reliable electrical connections, which is critical in high-frequency or sensitive applications.

Compromised Solderability: The presence of oxidized layers impairs the bonding process during assembly, which leads to weak or unreliable solder joints.

Surface Degradation: Over time, oxidation can discolor the gold-plated surface and create visible defects that signal broader reliability issues.

ENIG vs. Traditional Gold Plating

Different surface finish processes offer varying resistance to oxidation. ENIG (Electroless Nickel Immersion Gold) plating incorporates a nickel barrier between the gold and the copper base to provide robust protection against environmental factors — which makes ENIG a preferred choice for high-reliability applications. Pure gold plating is visually appealing and solderable, but lacks the protective nickel layer of ENIG, which makes it more prone to degradation over time.

Understanding these mechanisms highlights the importance of proper design, handling, and maintenance to mitigate oxidation risks.

Factors Leading to PCB Oxidation

Several factors contribute to the oxidation of gold-plated PCBs, but it often begins with environmental exposure. Humidity is one of the most significant contributors, as moisture facilitates the penetration of oxygen through microscopic defects in the gold layer. When coupled with pollutants such as sulfur and chlorine that are common in industrial and urban environments, these conditions accelerate oxidation and corrosion processes.

Handling practices are another critical factor. The oils, salts, and contaminants naturally present on human skin can transfer to PCB surfaces during manufacturing or assembly. These residues act as a catalyst for oxidation, especially when boards are exposed to high temperatures during soldering or storage. Even brief contact can lead to discoloration or tarnishing over time if not addressed with proper cleaning or protective measures.

Manufacturing quality also plays a crucial role. Uneven gold plating or insufficient thickness can leave the underlying copper or nickel layers exposed and create weak points susceptible to oxidation. Poor post-plating processes, such as inadequate cleaning or failure to remove residual chemicals, can further exacerbate the issue by leaving reactive substances on the board surface.

Finally, improper storage can drastically increase the likelihood of oxidation. Boards stored in uncontrolled environments, such as areas with fluctuating temperatures or high humidity, are particularly vulnerable. Over time, these conditions degrade the gold plating and reduce its effectiveness as a protective barrier. Recognizing these contributing factors is essential for implementing effective prevention strategies.

How to Prevent and Manage PCB Oxidation

Preventing oxidation in gold-plated PCBs involves a combination of design improvements, environmental controls, and careful handling practices. And ensuring a PCBs long-term reliability requires consistent maintenance and proactive measures to address environmental and operational risks. By incorporating regular inspection routines and restorative techniques, manufacturers and end-users can maintain their performance and reliability throughout their lifecycle.

Optimize Manufacturing Processes

High-quality pcb manufacturing is the first line of defense against oxidation. Ensuring the gold plating has a uniform thickness and sufficient coverage prevents oxygen from penetrating to the underlying layers. In ENIG finishes, a nickel barrier protects the copper substrate to provide an additional shield against corrosion. Post-manufacturing cleaning is equally critical, as residual chemicals left on the PCB surface can accelerate oxidation.

Control Environmental Exposure

Environmental conditions play a significant role in the rate of oxidation. Storing PCBs in a dry, temperature-controlled environment minimizes exposure to humidity and airborne contaminants. Using nitrogen-filled storage cabinets or vacuum-sealed packaging can further protect gold-plated PCB boards from reactive elements. Silica gel or other desiccants are also effective in absorbing moisture, particularly in regions with high humidity.

Apply Protective Coatings

Conformal coatings or specialized anti-oxidation sprays provide an added layer of protection for PCBs. These materials shield the board surface from direct exposure to oxygen, moisture, and pollutants, which reduces the risk of tarnishing. However, these coatings must be carefully selected to avoid interfering with the board’s electrical conductivity or solderability during assembly.

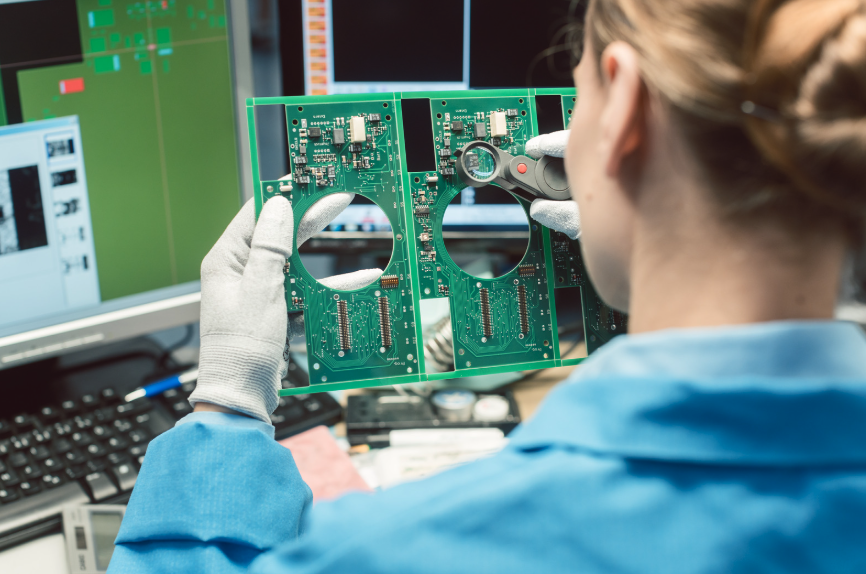

Routine Inspections for Early Detection

Periodic visual and functional inspections are essential to identify early signs of oxidation, wear, or contamination. Magnification tools can reveal discoloration, tarnishing, or surface irregularities, which may indicate the onset of oxidation. Catching these issues early allows for targeted cleaning or repairs before they affect the board’s functionality.

Implement Proper Handling Procedures

Handling gold-plated PCBs without gloves or anti-static tools introduces oils, salts, and debris that can accelerate oxidation. Technicians should always wear clean gloves and use tools designed to minimize physical contact with sensitive surfaces. Regular cleaning of PCBs using approved solvents can also remove contaminants and prolong their lifespan.

Cleaning and Restoration

Cleaning oxidized gold surfaces is a delicate but effective way to restore electrical performance. Approved solvents or mild abrasives can remove oxidation and contaminants without damaging the underlying gold layer. In more severe cases, chemical treatments or re-plating may be required to refurbish heavily degraded areas. It’s crucial to adhere to manufacturer-recommended procedures to avoid unintended damage.

Implementing Predictive Maintenance

Leverage predictive maintenance strategies, including data logging and environmental tracking, to anticipate potential failure points. Advanced monitoring tools can alert technicians to subtle changes in PCB performance, prompting preventative action before significant damage occurs. This approach reduces downtime and improves overall system reliability.

By integrating these practices into design, manufacturing, storage, and maintenance workflows, professionals can significantly reduce the likelihood of PCB oxidation. These proactive measures not only extend the lifespan of gold-plated PCBs but also ensure that they will perform reliably.

The Role of Standards in PCB Oxidation Prevention

Industry standards play a vital role in minimizing the risk of oxidation in gold-plated PCBs. By establishing consistent benchmarks for pcb design, materials, and processes, these standards ensure reliable performance while reducing the likelihood of defects caused by environmental or operational factors.

Material and Thickness Specifications

Standards such as IPC-4552 and IPC-6012 govern the thickness and composition of gold plating in PCBs. These guidelines specify minimum and recommended plating thickness levels to ensure sufficient protection against oxidation and mechanical wear. For instance, the IPC-4552 standard outlines requirements for ENIG finishes, including a nickel layer of 3–6 microns and a gold layer of 0.05–0.15 microns. These specifications are critical in ensuring the gold layer is thick enough to prevent oxygen penetration.

Environmental Compliance

In addition to material requirements, standards like IPC-A-610 specify acceptable environmental conditions for manufacturing, handling, and storage. Adhering to these guidelines ensures PCBs are not exposed to humidity, contaminants, or extreme temperatures during production and transit, all of which can exacerbate oxidation risks.

Manufacturing Process Control

IPC standards also focus on process consistency. For example, IPC-2221 establishes guidelines for plating uniformity and quality control during the manufacturing process. This ensures that gold-plated PCB boards maintain their integrity under various operational conditions. By promoting precise plating techniques and post-manufacturing cleaning protocols, these standards minimize the presence of impurities that could accelerate oxidation.

Benefits of Compliance

Meeting industry standards offers several advantages. It not only enhances the durability and performance of PCBs but also ensures compatibility with global supply chains. For manufacturers targeting critical sectors like aerospace or medical devices, compliance with these standards is often a prerequisite for certification, reinforcing trust in the reliability of their products.

Incorporating these standards into every stage of the PCB lifecycle — from design to deployment — provides a robust framework for mitigating oxidation risks. By aligning processes with these benchmarks, manufacturers can deliver gold-plated PCBs that perform consistently, even in challenging environments.

Sourcing Quality Gold-Plated PCBs

Gold-plated PCBs are integral to high-reliability electronics, but their performance hinges on protecting them from oxidation. By understanding the factors that lead to PCB oxidation and implementing measures such as proper manufacturing, storage, and handling practices, professionals can significantly extend the lifespan of these components.

Adherence to industry standards, such as those from IPC, ensures consistency in material quality and process control, providing a strong foundation for oxidation prevention. These proactive approaches not only safeguard the functionality of gold-plated PCB boards but also deliver long-term value in demanding applications.

And even if you have good maintenance and preventative measures in place, it always helps to have quality components to start with. Microchip USA supplies gold-plated electronics components to companies in a variety of industries using industry-leading quality control protocols to ensure the authenticity and quality of every part. We pride ourselves on providing top-tier customer service and on being able to supply even the most difficult-to-find parts. Contact us today!