How Does a Relay Work? A Complete Guide

More from the Category

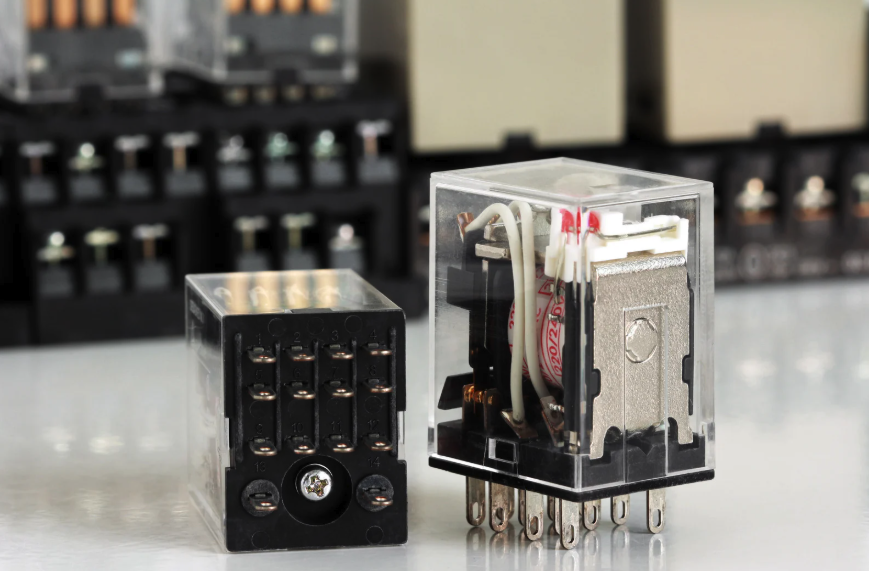

Relays are essential components in electronic and electrical systems, acting as electrically operated switches that control circuits.

They allow a low-power signal to control a high-power circuit, making them indispensable in automation, safety systems, and modern electronics. Understanding how relays work not only enhances your knowledge of circuit design but also helps you choose the right component for your application!

What is a Relay

A relay is an electromechanical or solid-state device that uses a small input signal to switch a larger load current. In simple terms, it works like a remote-controlled switch.

A Brief History

Relays have existed since the early days of telegraphy in the 19th century. Originally, they were used to amplify weak signals transmitted over long distances. Over time, their applications expanded to include industrial control, automotive systems, telecommunications, and home automation. Today, both electromechanical and solid-state designs exist, each optimized for different needs.

Common Applications

Relays are everywhere, from cars and consumer electronics to heavy machinery and smart homes. Automotive relays control headlights, wipers, and engine starters. In industrial settings, they manage motor loads, conveyor systems, and safety interlocks. In homes, they enable automation in lighting, HVAC systems, and security setups.

Types of Relays

Relays come in various forms, each designed to meet specific operational requirements. Here are the most important types you need to know:

Electromechanical Relays (EMRs)

Electromechanical relays are the traditional and most widely recognized type. They rely on an electromagnetic coil to physically move an armature, which opens or closes electrical contacts. When current flows through the coil, it generates a magnetic field that pulls the armature, completing the circuit. When the current stops, a spring returns the armature to its original position.

Advantages:

• Handles both AC and DC loads.

• Provides excellent isolation between control and load circuits.

• Affordable and widely available.

Disadvantages:

• Slower switching speed compared to solid-state relays.

• Mechanical wear and tear over time.

• Produces audible clicking sound during operation.

Solid-State Relays (SSRs)

Unlike EMRs, solid-state relays have no moving parts. Instead, they use semiconductors, such as thyristors or transistors, to switch electronically. When the control signal activates the SSR, it triggers a semiconductor device allowing current flow through the load circuit.

Advantages:

• Silent operation with no mechanical movement.

• Extremely fast switching speed.

• Longer operational life and higher durability in harsh environments.

Disadvantages:

• Higher cost than electromechanical relays.

• Generates heat during operation; may require heat sinks.

• Allows small leakage currents even in the “off” state.

Reed Relays

Reed relays are specialized devices that use thin metal reeds sealed within a glass envelope. When an electromagnetic field is applied, the reeds move together, closing the circuit. These relays are valued for their compact size and fast switching capabilities.

Advantages:

• Compact size and lightweight.

• Fast switching capability.

• Hermetically sealed design protects against contaminants.

Disadvantages:

• Limited current and voltage handling capacity.

• Not suitable for heavy-duty applications.

Time Delay Relays

Time delay relays introduce a programmable delay between receiving an input signal and switching the load circuit. They are used in systems requiring sequential control, such as conveyor belts, motor start sequences, and lighting systems.

Advantages:

• Ideal for sequencing processes and timed operations in automation.

• Common in industrial control, HVAC systems, and lighting applications.

Disadvantages:

• More complex and costly than standard relays.

• Limited timing adjustment range depending on model.

Other Specialized Types

Beyond these core categories, many specialized relays exist, thermal relays for overload protection, latching relays for maintaining state without continuous power, and safety relays designed for critical systems requiring redundancy and fail-safe operation.

How a Relay Works: Step by Step

Relays operate by using an electrical signal to control another circuit. Here’s a closer look at how it works:

Coil Energization: When a voltage is applied across the relay’s coil, current flows through it, generating a magnetic field. This electromagnetic force is the driving mechanism of an electromechanical relay.

Magnetic Attraction and Armature Movement: The magnetic field attracts the armature, a movable lever, toward the coil. This mechanical movement is what changes the state of the relay’s contacts.

Contact Switching: As the armature moves, the relay's contacts either close (for Normally Open, NO) or open (for Normally Closed, NC). This action completes or interrupts the circuit on the load side.

Spring Reset: When the coil is de-energized, the magnetic field collapses. A spring forces the armature back to its original position, resetting the contacts.

This process allows a low-voltage, low-current control signal to manage a high-voltage or high-current load safely, providing both control and electrical isolation.

Relay Circuit Examples

Real-world examples help illustrate the versatility of relays:

Simple Control Circuit: If a microcontroller operating at 5V needs to turn on a 12V LED strip, a relay acts as a bridge. The microcontroller energizes the relay coil, closing the contacts and allowing the 12V power to flow to the LED strip.

High-Voltage Switching: A home automation system might use a relay to control a 230V AC appliance like a water pump using a low-voltage smart controller signal. This provides safe control without exposing the low-voltage control circuit to hazardous mains voltage.

Automotive Starter Circuit: In vehicles, the ignition key activates a small current through a relay coil. This relay then switches the heavy current required by the starter motor, protecting the ignition switch from high loads.

Key Specifications to Understand

When choosing a relay, knowing its specifications is essential to ensure compatibility and safety:

Coil Voltage and Current: The voltage required to energize the coil (5V, 12V, 24V) and the current determine how much power your control circuit needs to activate the relay.

Contact Rating: Indicates the maximum voltage and current the contacts can safely switch (250V AC, 10A). Always select a relay rated higher than your load to avoid overheating and premature failure.

Switching Time: How quickly the relay transitions between states (typically 5–20 ms for EMRs, microseconds for SSRs).

Isolation Resistance: Defines how well the relay electrically separates the control and load circuits, critical for safety in high-voltage systems.

Mechanical and Electrical Life: Measured in switching cycles. Electromechanical relays have millions of mechanical cycles, but fewer under load; SSRs last far longer due to having no moving parts.

Applications

Relays are everywhere. Here are some practical applications:

Home Automation: Control lighting, fans, and HVAC systems via smart devices using relays as the interface between low-voltage controllers and mains power.

Industrial Automation: Manage motors, pumps, conveyor belts, and robotic arms. Time delay relays and safety relays ensure processes run sequentially and safely.

Automotive Electronics: Power windows, headlights, fuel injection systems, and ignition rely on relays to switch high-current loads efficiently and safely.

Safety and Protection Systems: Relays act as circuit breakers in sensitive systems, disconnecting loads during overcurrent or fault conditions.

Troubleshooting and Best Practices

Relays can fail, but understanding why helps prevent issues:

Common Failures

• Contact pitting from arcing during switching.

• Coil burnout caused by overvoltage or continuous duty beyond ratings.

• Mechanical wear in EMRs due to high cycle counts.

How to Diagnose

• Visual inspection for burned or welded contacts.

• Test coil resistance with a multimeter, open circuit indicates failure.

• Check if the relay clicks when powered; no sound could mean a stuck armature or dead coil.

Best Practices

• Use relays rated higher than your load requirements.

• Add flyback diodes across relay coils to prevent voltage spikes in DC circuits.

• For AC loads, consider snubber circuits to reduce arcing and extend relay life.

• Mount relays away from high-heat areas and ensure proper ventilation for SSRs.

Relay vs Transistor: When to Use Which

Both relays and transistors function as switches, but their use cases differ:

Relays

• Provide complete electrical isolation between control and load circuits.

• Can switch AC or DC loads at high voltages and currents.

• Slower and larger, better for mechanical or heavy-duty switching.

Transistors

• Excellent for high-speed switching in low-power electronic circuits.

• Lack isolation; require additional components to switch AC mains safely.

• Ideal for logic-level or signal switching rather than heavy loads.

Learn More: What Do Transistors Do?

Decision Rule

• Use relays when you need isolation or high-voltage/high-current switching.

• Use transistors for compact, fast-switching, low-power control.

Relays and Beyond: Building with Confidence

Relays are indispensable components in modern electronics, offering safe and reliable switching for a wide range of applications, from home automation to industrial control and automotive systems. By understanding how relays work, the different types available, and their key specifications, you can make informed decisions that enhance both performance and safety in your designs.

Whether you’re working on a new project or maintaining existing systems, choosing the right relay is crucial for long-term reliability.

Need High-Quality Relays? Microchip USA Has You Covered!

At Microchip USA, we supply a wide range of premium relays and other high-quality electronic components. Our team ensures fast delivery, competitive pricing, and expert support to help you find the perfect component for your project.

Ready to get started?

Contact us for personalized assistance, or browse our extensive inventory of relays and electronic components to keep your designs running smoothly.