FPGA vs ASIC: Choosing the Right Solution For Your Design

More from the Category

In the world of digital design, few decisions carry as much weight as choosing between an FPGA and an ASIC. These two technologies sit at the heart of modern electronics, powering everything from smartphones to satellites. But while they may seem similar at first glance, their differences are profound, and so are the implications for your project.

FPGAs, or Field-Programmable Gate Arrays, are the Swiss Army knives of the semiconductor world. They’re flexible, reconfigurable, and perfect for prototyping. Need to test a new design or adapt to changing requirements? FPGAs have you covered. On the other hand, ASICs — Application-Specific Integrated Circuits — are the precision tools. Custom-built for a single purpose, they deliver unmatched performance and efficiency, especially at scale.

But here’s the catch: there’s no one-size-fits-all answer. The choice between FPGA and ASIC depends on a myriad of factors, from budget and timeline to performance and power requirements. Get it right, and you’ll unlock new possibilities for your design. Get it wrong, and you could face costly delays or missed opportunities.

This article dives into the FPGA vs ASIC debate, exploring their strengths, weaknesses, and the strategic considerations that can help you make the right choice. Whether you’re designing a cutting-edge AI accelerator or a rugged industrial controller, the insights here will guide you toward the solution that best fits your needs.

Understanding FPGA and ASIC

To make an informed decision between an FPGA and an ASIC, it’s essential to understand what each technology is, how they work, and where they excel. Let’s start by breaking down the basics.

What is an FPGA?

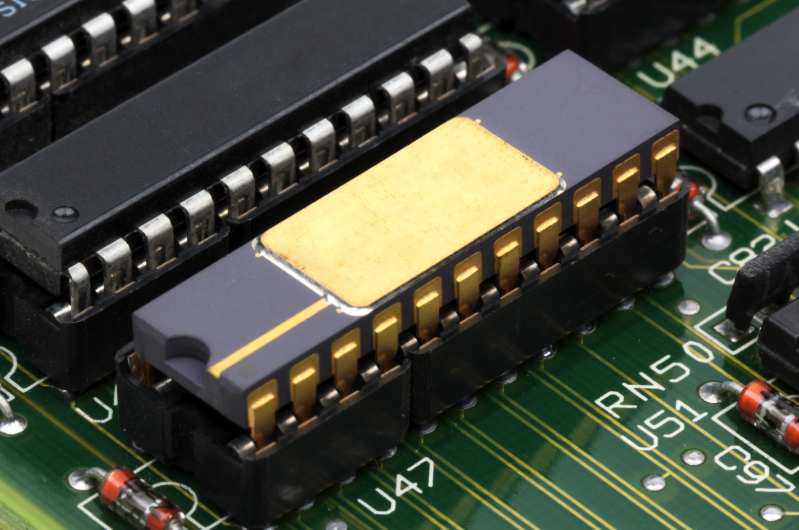

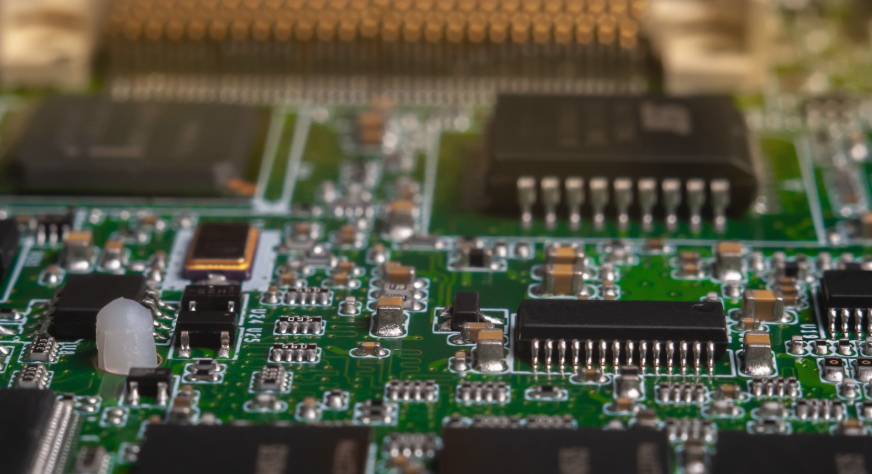

An FPGA, or Field-Programmable Gate Array, is a reconfigurable semiconductor device. Think of it as a blank canvas that engineers can program and reprogram to perform specific tasks. This flexibility makes FPGAs ideal for applications where requirements may change over time or where rapid prototyping is needed.

FPGAs consist of an array of programmable logic blocks and interconnects, which can be configured to implement complex digital circuits. They’re widely used in telecommunications, automotive, and aerospace industries, where adaptability and fast time-to-market are critical. For example, FPGAs are often used in 5G base stations to handle evolving standards and protocols.

What is an ASIC?

An ASIC, or Application-Specific Integrated Circuit, is a custom-designed chip tailored for a specific application. Unlike FPGAs, ASICs are fixed-function devices — once manufactured, their functionality cannot be changed. This lack of flexibility is offset by significant advantages in performance, power efficiency, and cost at scale.

ASICs are designed from the ground up to meet the exact needs of a particular application, making them highly optimized. They’re commonly found in consumer electronics, such as smartphones and smartwatches, where performance and power efficiency are paramount. For instance, the chips powering AI accelerators in data centers are often ASICs, designed to handle massive computational workloads with minimal energy consumption.

FPGA vs ASIC: Key Differences

The choice between FPGA and ASIC isn’t just about picking a technology — it’s about understanding how each aligns with your project’s goals. From flexibility to cost, performance to power efficiency, the differences between these two technologies are stark. Let’s dive into the key areas where FPGA and ASIC diverge.

Flexibility vs Optimization

FPGAs are the ultimate multitaskers. Their reconfigurable nature allows engineers to modify designs even after deployment, making them ideal for applications where requirements may evolve. For example, in telecommunications, FPGAs can adapt to new protocols or standards without requiring a hardware redesign.

ASICs, on the other hand, are specialists. They’re designed for a single purpose, offering unparalleled performance and efficiency for that specific task. Once manufactured, their functionality is fixed, which means they’re less adaptable but highly optimized. This makes ASICs the go-to choice for applications like AI acceleration or mobile processors, where every milliwatt of power and nanosecond of latency matters.

Time to Market

If speed is your priority, FPGAs have a clear advantage. They allow engineers to prototype quickly and iterate designs, significantly reducing development time. This is particularly valuable in industries like automotive or aerospace, where time-to-market can make or break a product.

ASICs, by contrast, require a longer development cycle. Depending on the complexity, designing and fabricating a custom chip can take months or even years. However, once the ASIC is ready, it offers long-term benefits in performance and cost efficiency, especially for high-volume production.

Cost Considerations

Cost is often the deciding factor in the FPGA vs ASIC debate. FPGAs have lower upfront costs since they don’t require custom fabrication. This makes them attractive for low-volume projects or applications where flexibility is needed.

ASICs, however, involve significant upfront investment. The design, verification, and fabrication processes are expensive and time-consuming. But once the initial costs are covered, ASICs offer lower unit costs at scale, making them cost-effective for high-volume production.

Power Efficiency

When it comes to power consumption, ASICs are the clear winners. Their custom design eliminates the overhead associated with programmability, resulting in highly efficient operation. This makes ASICs ideal for battery-powered devices like smartphones and wearables.

FPGAs, while versatile, consume more power due to their reconfigurable architecture. This can be a drawback in power-sensitive applications, though advancements in FPGA technology are gradually narrowing the gap.

Strategic Considerations for Choosing Between FPGA and ASIC

Choosing between FPGA and ASIC isn’t just about picking a technology—it’s about aligning your decision with the broader goals of your project. Each option comes with its own set of trade-offs, and understanding these is key to making an informed choice. Let’s dive deeper into the strategic considerations engineers must weigh when deciding between FPGA and ASIC.

Project Requirements

The first and most critical factor is understanding the specific needs of your project. What are the performance, power, and flexibility requirements? Are you building a prototype, or is this a product ready for mass production?

For example, FPGAs are ideal for applications where flexibility and adaptability are paramount. If you’re working on a research project or developing a system that may need to evolve over time, such as a 5G base station or a military communication system, FPGAs allow you to reprogram and update the hardware as needed. This makes them a powerful tool for innovation and experimentation.

On the other hand, ASICs are designed for specific tasks and excel in applications where performance and efficiency are critical. If you’re developing a high-volume product like a smartphone or a wearable device, ASICs offer the optimized performance and low power consumption needed to stay competitive. Their custom design ensures that every transistor is used efficiently, making them the gold standard for mass-produced electronics.

Budget and Scale

Budget is often the deciding factor in the FPGA vs ASIC debate. FPGAs have lower upfront costs because they don’t require custom fabrication. This makes them an attractive option for startups, small-scale projects, or applications where the production volume is low. For instance, if you’re building a niche product or a proof-of-concept, FPGAs allow you to get started without a significant financial commitment.

However, FPGAs come with higher unit costs, which can become a disadvantage at scale. If your project involves producing millions of units, the cost per FPGA can quickly add up. This is where ASICs shine. While the initial investment in designing and fabricating an ASIC can be substantial — often running into millions of dollars — the cost per unit drops significantly at high volumes. For large-scale production, ASICs can be far more cost-effective in the long run.

Time Constraints

Time-to-market is another critical consideration. In industries where speed is essential, such as consumer electronics or automotive, being first to market can make or break a product. FPGAs offer a significant advantage here. Their reconfigurable nature allows for rapid prototyping and faster development cycles. You can design, test, and iterate quickly, reducing the time it takes to bring your product to market.

ASICs, by contrast, require a longer development cycle. Designing a custom chip involves multiple stages, including architecture design, verification, fabrication, and testing. This process can take months or even years, depending on the complexity of the design. However, once the ASIC is ready, it offers long-term benefits in performance, power efficiency, and cost savings. If your project has a longer timeline and the luxury of extended development, ASICs may be the better choice.

Power Efficiency

Power consumption is a key consideration, especially for battery-powered devices or energy-sensitive applications. ASICs are highly power-efficient because they’re custom-designed for a specific task. Every aspect of the chip is optimized to minimize energy consumption, making ASICs ideal for devices like smartphones, wearables, and IoT sensors.

FPGAs, while versatile, consume more power due to their programmable nature. The overhead associated with reconfigurability means that FPGAs are less efficient than ASICs. However, advancements in FPGA technology are gradually narrowing this gap. For example, modern FPGAs now feature power-saving modes and optimized architectures that reduce energy consumption. Still, if power efficiency is a top priority, ASICs are often the better choice.

Future-Proofing

Finally, consider the potential for future changes. Will your design need to adapt to new standards, technologies, or market demands? FPGAs offer the flexibility to update and reconfigure, making them a safer bet for applications where requirements are likely to evolve. For instance, in industries like telecommunications or automotive, where standards and protocols are constantly changing, FPGAs provide the adaptability needed to stay ahead of the curve.

ASICs, once manufactured, are fixed in functionality. This makes them less adaptable but highly reliable for stable, well-defined applications. If your project involves a mature technology with little room for change—such as a microcontroller or a memory chip — ASICs provide a robust, long-term solution.

Making the Right Choice

The FPGA vs ASIC debate is a strategic decision that will shape the trajectory of your project. FPGAs offer unparalleled flexibility and rapid development, making them ideal for prototyping and applications where requirements may evolve. ASICs, on the other hand, deliver unmatched performance, power efficiency, and cost savings at scale, making them the go-to choice for high-volume production and specialized tasks.

The key to making the right choice lies in understanding your project’s unique needs. Consider factors like budget, timeline, performance requirements, and the potential for future changes. By aligning your decision with these considerations, you can ensure that your design not only meets today’s demands but also stands the test of time.

In the end, there’s no one-size-fits-all answer. Whether you choose FPGA or ASIC, the most important thing is to make an informed decision — one that balances flexibility, performance, and cost to achieve your goals.

Whether you choose FPGAs or ASICs for your project, Microchip USA can supply them, and even manage your entire supply chain. As the premier independent supplier of board level electronics, our team of procurement specialists has worked with more than half of the Fortune 500 companies to supply tens of millions of components. Contact us today!